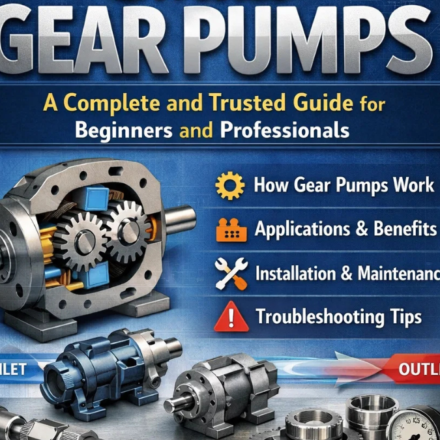

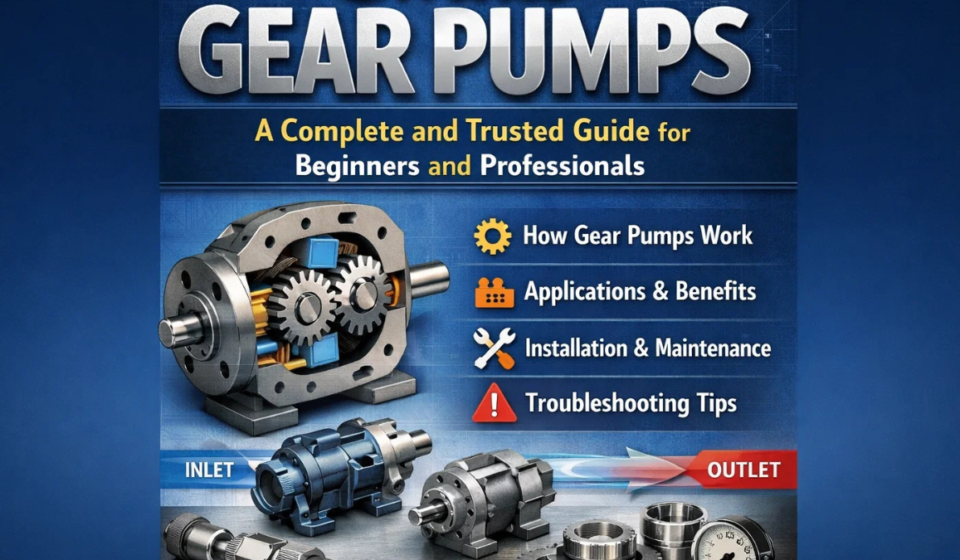

Small Gear Pumps: A Complete and Trusted Guide for Beginners and Professionals

Small gear pumps are everywhere, even if most people don’t notice them. From moving oil in machines to handling chemicals in factories, these compact devices quietly do their job day in and day out. If you’ve ever wondered how fluids move smoothly and reliably in tight spaces, small gear pumps are a big part of the answer.

This article is a fully detailed, easy-to-read, and expert-level guide on small gear pumps. It’s written in Grade 7 English, but it doesn’t talk down to you. Instead, it explains things clearly, step by step, using real-world examples, simple language, and practical insights. By the end, you’ll understand what small gear pumps are, how they work, where they’re used, and why they’re trusted across so many industries.

Let’s dive in and get comfortable with the world of small gear pumps.

Understanding Small Gear Pumps and Why They Matter

Small gear pumps are mechanical devices designed to move liquids using rotating gears. They may be small in size, but don’t let that fool you they’re powerful, reliable, and incredibly precise. These pumps are often used when a steady flow of fluid is needed, especially in compact systems.

What makes small gear pumps special is their ability to handle thick fluids, maintain consistent pressure, and work in tight spaces. Whether it’s oil, fuel, chemicals, or food-grade liquids, these pumps get the job done without much fuss.

In simple terms, small gear pumps:

- Move fluids smoothly

- Deliver a steady flow

- Work well in limited spaces

- Last a long time with proper care

Because of these qualities, they’re trusted in industries where accuracy and reliability truly matter.

How Small Gear Pumps Work in Simple Words

At first glance, the inside of a gear pump might look complicated, but the idea behind it is pretty straightforward.

Inside small gear pumps, there are two or more gears that mesh together. When these gears rotate:

- Fluid enters the pump at the inlet

- The gears trap the fluid between their teeth and the pump housing

- The fluid is carried around the outside of the gears

- The fluid exits through the outlet under pressure

That’s it. No valves. No complex parts. Just gears doing what gears do best.

Because of this simple design, small gear pumps are:

- Easy to understand

- Easy to maintain

- Very dependable

And honestly, that simplicity is one of their biggest strengths.

Key Components of Small Gear Pumps Explained

To truly understand small gear pumps, it helps to know their main parts. Each component plays a role, and together, they create a smooth, efficient system.

Main Parts of Small Gear Pumps

- Gears

These are the heart of the pump. They rotate and move the fluid. - Pump Housing

This outer shell holds everything together and guides the fluid flow. - Inlet Port

Where the fluid enters the pump. - Outlet Port

Where the fluid exits the pump under pressure. - Shaft

Connects the gears to the motor that powers the pump. - Seals and Bearings

These prevent leaks and reduce friction.

Each part is carefully designed to handle pressure, temperature, and the type of fluid being pumped. When all parts work in harmony, small gear pumps perform smoothly and efficiently.

Types of Small Gear Pumps Used in Industry

Not all small gear pumps are the same. Different designs are used depending on the application and fluid type.

External Gear Pumps

These are the most common type of small gear pumps. They use two identical gears that rotate against each other.

Key features:

- Simple design

- High efficiency

- Good for clean fluids

Internal Gear Pumps

These pumps use one internal gear and one external gear. One gear rotates inside the other.

Key features:

- Quieter operation

- Good for thicker fluids

- Smooth and steady flow

Lobe-Style Gear Pumps

Though slightly different, these are often grouped with gear pumps.

Key features:

- Gentle on fluids

- Used in food and pharmaceutical industries

- Easy to clean

Choosing the right type of small gear pump depends on what you’re pumping and how you’re using it.

Common Applications of Small Gear Pumps

You might be surprised by how often small gear pumps are used. They show up in more places than most people expect.

Industrial Uses

- Hydraulic systems

- Lubrication systems

- Chemical transfer

- Fuel handling

Automotive Applications

- Engine oil circulation

- Fuel delivery systems

- Transmission fluid transfer

Food and Beverage Industry

- Syrups and oils

- Flavorings

- Food-grade liquids

Medical and Laboratory Equipment

- Precise fluid dosing

- Controlled chemical delivery

Because small gear pumps offer accuracy and reliability, they’re often chosen for tasks where mistakes just aren’t acceptable.

Advantages of Using Small Gear Pumps

There’s a reason small gear pumps have been around for so long. They bring a lot to the table.

Major Benefits

- Consistent Flow Rate

The flow doesn’t jump around. It stays steady. - Compact Size

Perfect for tight spaces and small systems. - High Pressure Capability

They can push fluids where other pumps struggle. - Durability

With proper care, they last for years. - Low Maintenance

Fewer parts mean fewer problems.

Simply put, small gear pumps are dependable workhorses that don’t ask for much in return.

Limitations and Challenges of Small Gear Pumps

No device is perfect, and small gear pumps are no exception. Knowing their limits helps you use them wisely.

Common Challenges

- Not ideal for fluids with large solid particles

- Can wear faster with abrasive materials

- Fixed flow rate unless speed is adjusted

That said, many of these challenges can be managed by:

- Choosing the right materials

- Using proper filtration

- Following manufacturer guidelines

When used correctly, these limitations rarely become deal-breakers.

Materials Used in Manufacturing Small Gear Pumps

The material of a pump matters a lot. It affects durability, safety, and performance.

Common Materials

- Cast Iron

Strong and cost-effective for general use. - Stainless Steel

Corrosion-resistant and ideal for food or chemicals. - Bronze

Good for marine and fuel applications. - Engineering Plastics

Lightweight and resistant to certain chemicals.

Here’s a quick comparison to make things clearer:

| Material | Best For | Key Benefit |

|---|---|---|

| Cast Iron | Industrial oils | Durable and affordable |

| Stainless Steel | Food & chemicals | Corrosion resistance |

| Bronze | Fuel & marine use | Smooth operation |

| Plastic | Light chemicals | Lightweight and non-reactive |

Choosing the right material ensures your small gear pumps stay safe, efficient, and long-lasting.

How to Choose the Right Small Gear Pumps for Your Needs

Picking the right pump doesn’t have to feel overwhelming. It’s all about asking the right questions.

Things to Consider

- What type of fluid are you pumping?

- How thick is the fluid?

- What flow rate do you need?

- What pressure will the pump face?

- Is space limited?

Answering these questions helps narrow down the best small gear pumps for your application. When in doubt, consulting a pump specialist can save time, money, and headaches.

Maintenance Tips to Extend the Life of Small Gear Pumps

A little care goes a long way. Proper maintenance keeps small gear pumps running smoothly and avoids unexpected breakdowns.

Simple Maintenance Practices

- Check seals and bearings regularly

- Use clean, filtered fluids

- Monitor noise and vibration

- Follow lubrication guidelines

- Replace worn parts early

Ignoring maintenance is like skipping oil changes in a car it might work for a while, but trouble is just around the corner.

Safety Considerations When Using Small Gear Pumps

Safety always comes first, especially in industrial settings.

Key Safety Tips

- Never run the pump dry

- Avoid exceeding pressure limits

- Use proper protective equipment

- Install pressure relief valves

When handled responsibly, small gear pumps are safe, predictable, and easy to control.

Future Trends and Innovations in Small Gear Pumps

The world of small gear pumps isn’t standing still. New designs and technologies are making them even better.

What’s Changing

- Improved materials for longer life

- More energy-efficient designs

- Quieter operation

- Better sealing technology

As industries demand more precision and efficiency, small gear pumps continue to evolve. It’s safe to say they’ll remain a key part of fluid handling systems for years to come.

Final Thoughts on Small Gear Pumps

Small gear pumps may not grab headlines, but they’re essential behind-the-scenes players in countless systems. Their simple design, steady performance, and proven reliability make them a trusted choice across industries.

From factories and vehicles to food processing and medical equipment, small gear pumps deliver consistent results without drama. They’re compact, durable, and efficient qualities that engineers and operators truly appreciate.

In the end, when reliability matters and space is tight, small gear pumps are often the smart, dependable solution. With the right selection, proper maintenance, and safe operation, these pumps will keep things flowing smoothly for a long time to come.